| |

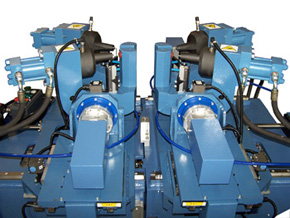

AUTOMATIC PUNCHING SYSTEM

The Automatic punching system PROGE 46 has been specially developed to punch automatically holes onto cookware shells.

The power and the great flexibility of the machine allow it to punch from 1 to 4 holes simultaneously onto cookware shells of any type of material either aluminium, stainless steel copper triply etc.

The special design of the PROGE 46 allows it to punch the holes at different height and different distance between hole centres.

The machine is operated hydraulically and pneumatically, which makes it:

easy to operate, to reconfigure , to set up and maintain, to control from the main panel, highly flexible when producing lots of multiple sizes in a single shift.

All PROGE 46 functions are controlled electronically by means of PLC. Simple keyboard operations carried out on the control panel allow the operator to determine cycle times and execute different operating programmes. The programming system is based on self learning movements that allow the operator to develop different punching programs in a very short time and store in the PLC main memory.

The machine fully complies with current CE standards regarding health and safety, particularly with respect to noise levels.

The operator of this machine takes care only of the loading & unloading of the cookware and the handles while adjustable centring systems avoid production reject and minimize the possibility of human error. Pick & Place systems can feed this machine directly after the pressing operation. |

|